COCHRAN, Ga. — Cotton is king in the South, but if you look at the numbers, it’s royalty in Georgia.

The Georgia Cotton Commission says the crop brings in $1 billion a year and generates 15,000 jobs on average.

59 cotton gins dot the Georgia landscape, with one of them in Cochran.

The sound of trains is something you’ll hear often there, but there’s another sound that’s always present.

“Everybody knows the hum of the gin. You can hear it when you get home, you can hear it in your sleep a lot of times and I think the boss wakes up in the middle of the night listening for the hum,” said manager Dennis Howell.

This time of year, the boss can rest easy. The Cochran Oil Mill and Ginnery runs 24 hours a day, six days a week. Howell is the manager and says cotton has always found a way into his life.

“I was in the dry-cleaning business for about 15 years,” he said.

But now he’s in the business of cleaning up cotton, which is essentially what a cotton gin does.

Here’s how it works…

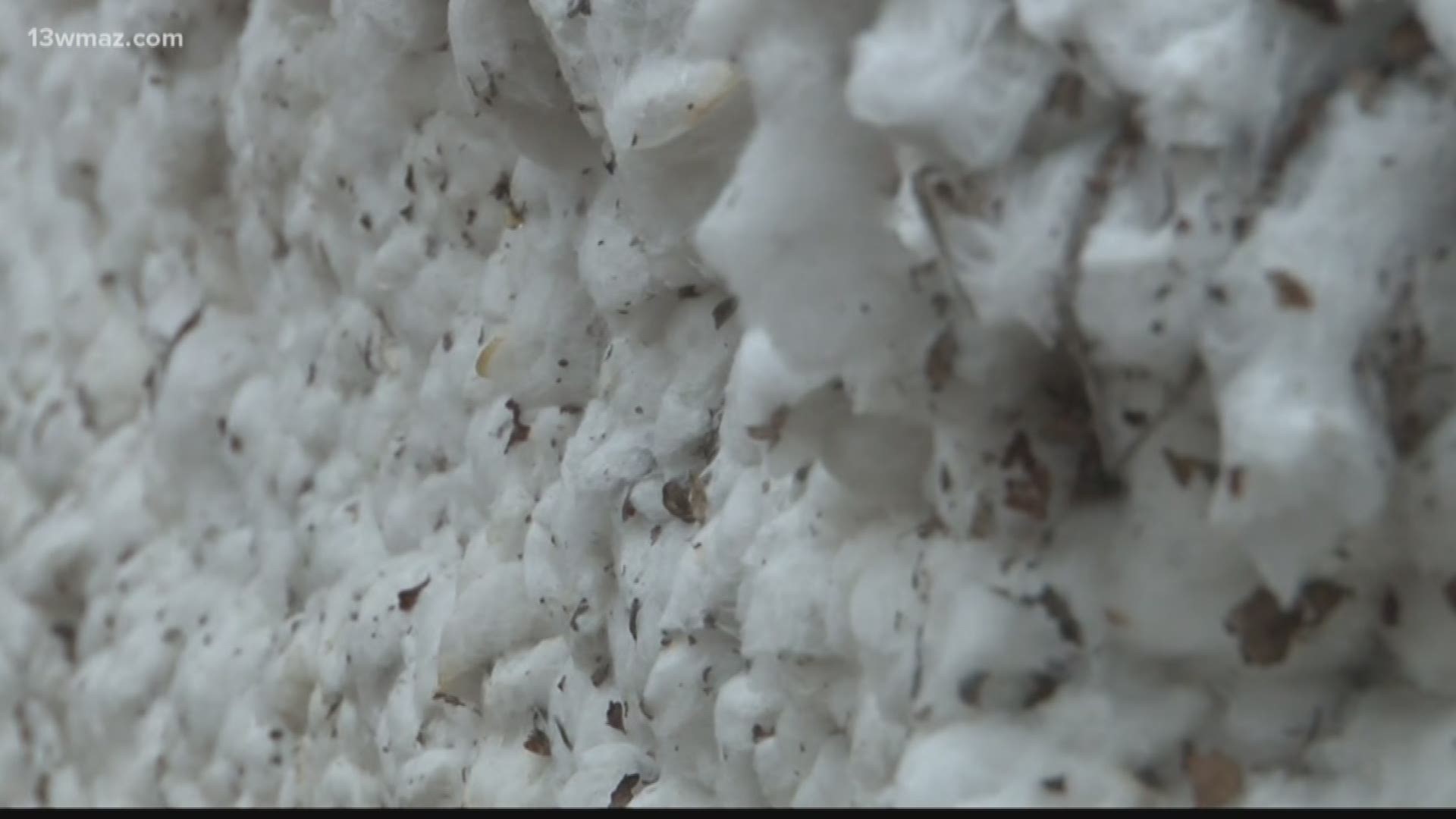

Cotton from the field comes in on big trucks to the loading area. It moves along slow chains into the first phase.

“The chains are taking it in, you can see the rollers up there with the spikes on it and that’s tearing the cotton apart, and it’s shooting it inside that pipe to the gin there,” said Howell.

It looks like a cartoon show up there, but that’s where the small saws do their heavy lifting. From there, it travels along a pipe to the actual gin machine.

This is where the magic happens. All the steel takes the tiny seeds right out of the cotton and they look like little dancing pebbles that shoot down into their own storage container. Fear not, everything here is used.

“Primarily cotton seed is used as cattle feed and cotton seed oil can be extracted from that and that's used in salad dressings, mayonnaise, and other products,” said Howell.

It’s bagged, tagged, and put into a warehouse.

500 pounds in one bale is a lot of cotton, and it feels like a rock. Howell says that out of one bale, you can get around 700 towels and 215 pairs of jeans.

The Cochran operation puts out 28,000 500-pound bales in a year, and this year is projected to be a good one.

“It's a pretty incredible process from start to finish from the field to the bales here. It's amazing,” said Howell.

It’s a little loud, but it's the sweet sound of a machine that dates back hundreds of years.

The cotton gin we use today is basically the same machine Eli Whitney designed, but of course technology has taken hold, so computers and automation have made lots of improvements.

RELATED HEADLINES

STAY ALERT | Download our FREE app now to receive breaking news and weather alerts. You can find the app on the Apple Store and Google Play.

STAY UPDATED | Click here to subscribe to our Midday Minute newsletter and receive the latest headlines and information in your inbox every day.

Have a news tip? Email news@13wmaz.com, or visit our Facebook page.